Business scope:

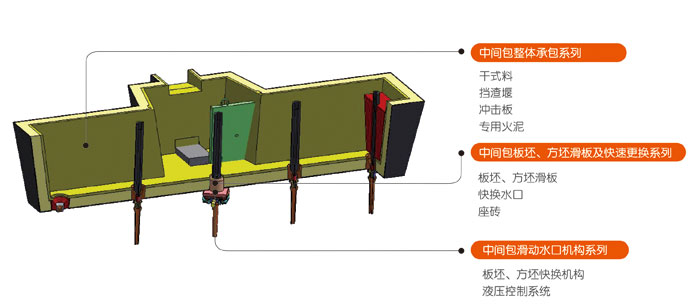

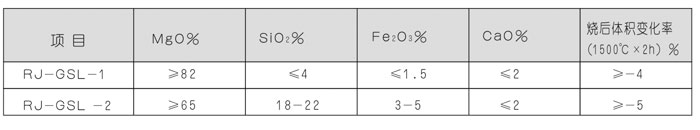

Castables for permanent lining, MgO dry vibration mix and coating material for working lining, tundish fast replaceable metering nozzle and mechanism, monostopper, ladle shroud, SEN, tundish furniture etc.

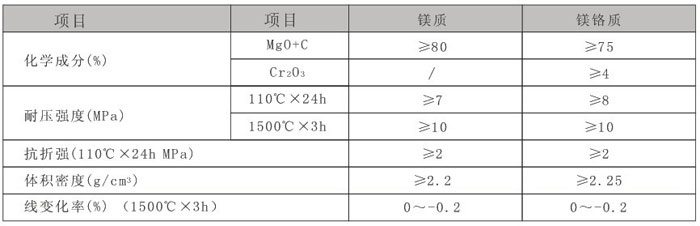

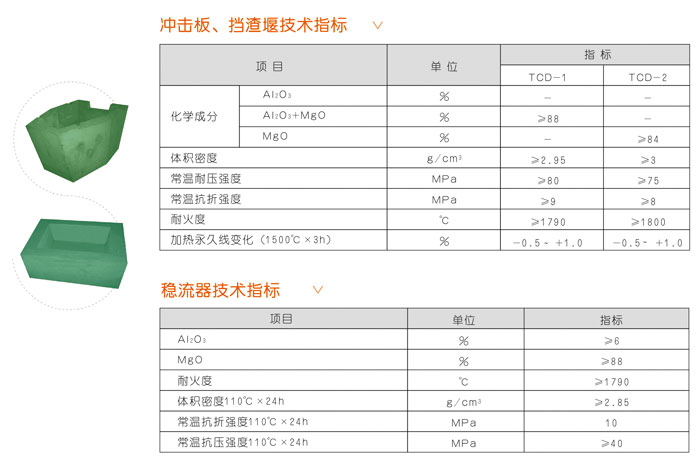

Tundish Impact Pad, Slag Dam and Stabilizer

Tundish impact pad, slag dam and stabilizer supplied by Henan Rongjin High Temperature Materials Co., Ltd. are shaped blocks precasted by alumina-magnesia and magnesia basic castables. All the products are characterized with good erosion resistance, excellent high temperature performance, good thermal shock resistance and long service life.

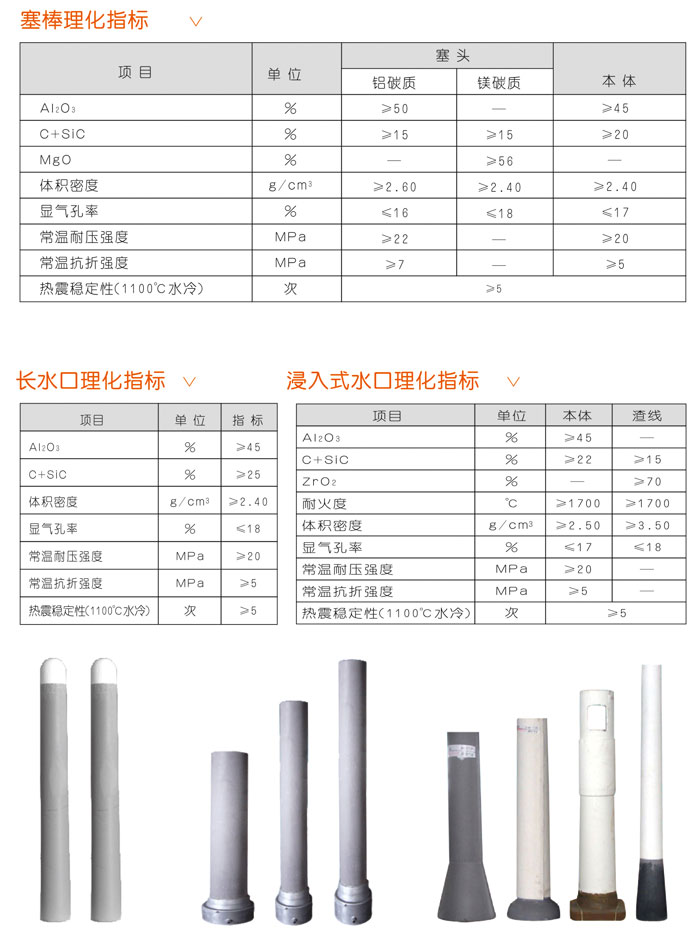

Monoblock stopper, Ladle shroud, SEN

Monolithic stopper is used mainly for flow control on molten steel poured from tundish to mould. Monolithic stopper is installed in the tundish, and the gap between stopper head and nozzle is adjusted for molten steel flow control. Argon can be blown into the tundish through argon inlet to prevent nozzle from clogging.

Monoblock stopper, Ladle shroud, SEN

Monolithic stopper is used mainly for flow control on molten steel poured from tundish to mould. Monolithic stopper is installed in the tundish, and the gap between stopper head and nozzle is adjusted for molten steel flow control. Argon can be blown into the tundish through argon inlet to prevent nozzle from clogging.

Ladle Shroud is one of functional refractories used to prevent molten steel from oxidization and splashing, when molten steel is poured from steel ladle into tundish via ladle shroud.

Submerged entry nozzle (SEN) is installed between tundish and mould to improve quality of the continuous casting products. Principal functions of submerged entry nozzle is, on one hand, to cover molten steel from being oxidized during its pouring from tundish to mould; and on the other hand, to evenly distribute molten steel into mould, as well as controlling flow condition of molten steel in the mould.